Here’s a scenario taken right from the trials and tribulations of a tech over at Appliantology: you’re troubleshooting a no heat complaint on a GE electric dryer. You start your troubleshooting with the heating circuit, and your findings are puzzling: there are 120 volts on either side of the heater with respect to neutral, but when you do a voltage reading across the heater, you get some weird amount like 80 volts. What gives?

There are a couple of things going on here, and one is easily remedied: you need to start using a loading meter. That weird 80 volts you’re seeing? Ghost voltage. I’ve already written about what ghost voltage is and how to avoid being tricked by it, so you should click here to check that post out if you haven’t already.

Once you start using a loading meter, like you always should for AC loads, you’ll find that you’ve actually got 0 volts across that heater. But we’re still left with a mystery: why are we reading 120 volts on either side of the heater wrt neutral, but not 240 across it? Is this just an example of an open heater?

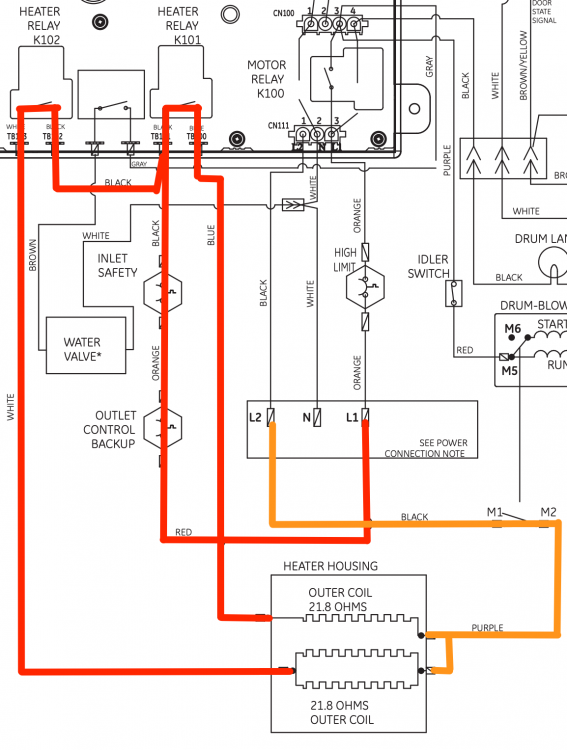

Not so fast. First, let’s look at the schematic and see how this circuit is supposed to function.

Here’s L1 traced out in red, and L2 traced out in orange. Standard stuff for a 240 VAC load. But what would happen if one of those voltage legs were missing? Let’s see how that would look:

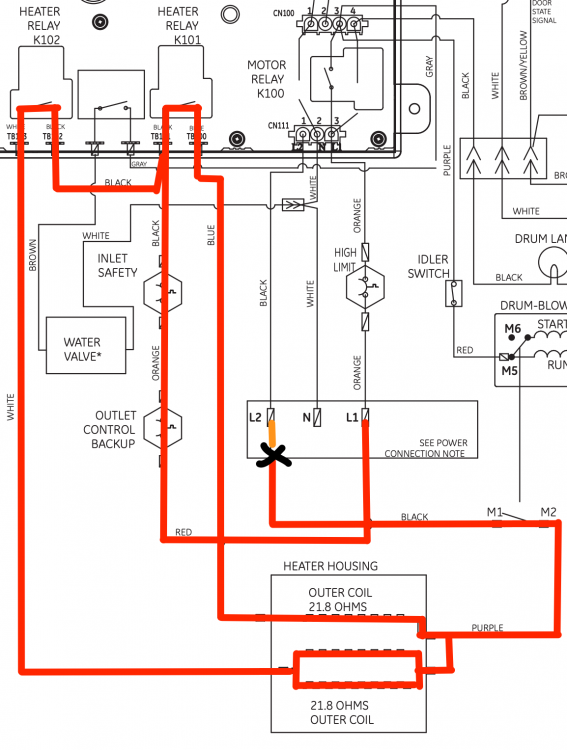

I’ve put a break in L2 in the form of that black X. Here’s what happens: since we no longer have a valid circuit, there’s no current flow. Without current flow, there’s no voltage drop. That means that if voltage is present on one side of a conductor, even a load like the heating element, it will also be present on the other side, since it doesn’t get dropped.

We now see how we got that reading earlier: we were reading L1 on both sides of the heating element. And since L1 has no voltage difference with itself, our loading meter told us there were 0 volts across the heating element.

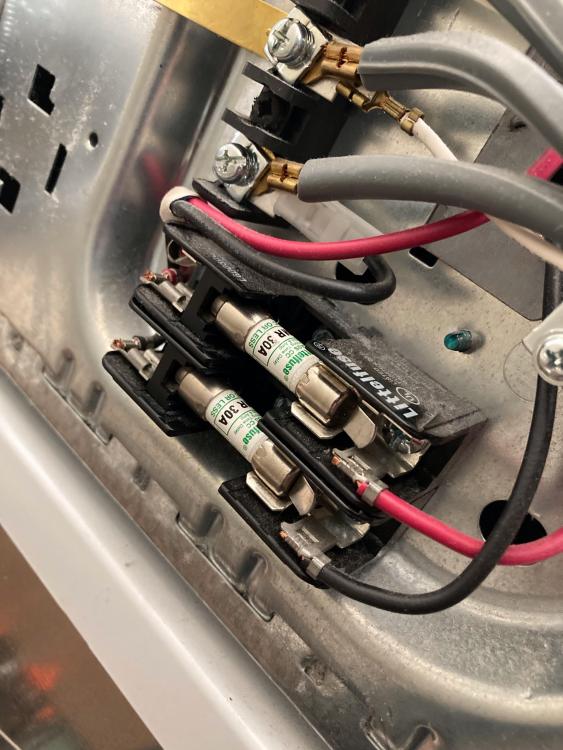

And wouldn’t you know it — those marked-up schematics show exactly what happened in our little case study. There’s a fuse for each line on the terminal block, and one of them had popped, effectively creating the scenario I described above.

Want to learn more about how voltage works in a circuit and how to apply that knowledge to real world troubleshooting? Click below to check out our Core Appliance Repair Training course right here at the Master Samurai Tech Academy.