Join me on another short troubleshooting journey — this one taken from a real tech’s experience that he posted on Appliantology.

You’re troubleshooting a Samsung dryer that won’t start– the control panel will let you select a cycle, but it won’t actually run if you press the start button. But the real head-scratcher is that, despite not being able to start a cycle, the machine always runs when the door is closed.

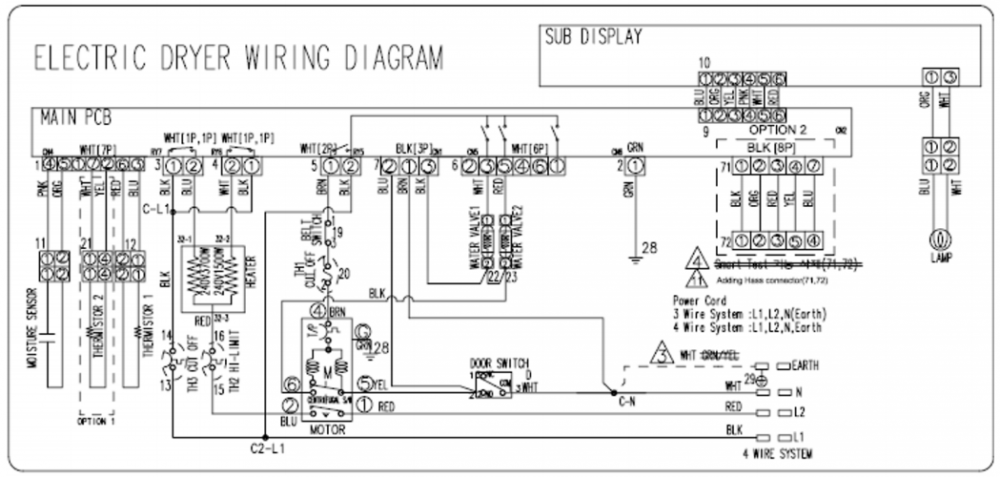

Sounds tricky, but as you’ll see, the troubleshoot is pretty simple if you have a solid troubleshooting strategy. Any good troubleshooting strategy always starts with the schematic, so let’s go there.

Pretty standard for a Samsung dryer. Our first order of business is to select an LOI — a load of interest. That’s the load that’s not doing what it’s supposed to do or that’s doing stuff when it’s not supposed to do anything. In our case, this is the motor. It’s running even when you haven’t started a cycle, so something in its circuit or power supply must be off.

Now that we’ve selected our load, let’s analyze its circuit:

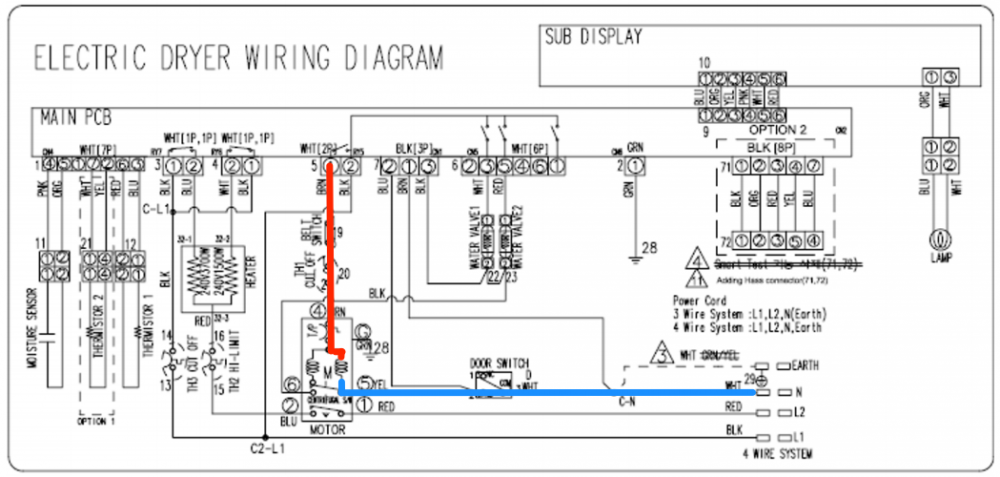

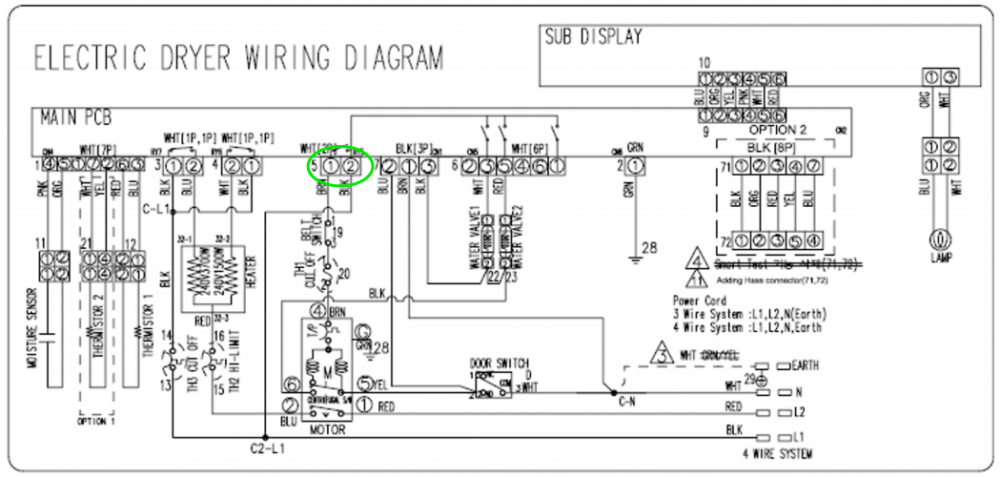

You might already be seeing that there’s only one thing that could be causing the problem here. Sure, there are plenty of things in the motor’s circuit that could interrupt its power supply, but there’s only one that could supply power when it’s not supposed to, and that’s the board. More specifically, relay 5 on the board.

The question then becomes why that relay is closed, even when a cycle isn’t started. Could it be a problem with the board’s algorithm? Are the logic circuits all scrambled? Do we have to be a computer whiz to get to the bottom of this?

Not at all. The truth is that electromechanical relays like this can just get stuck closed sometimes. It’s one of the ways they fail as they age, and a new control board will get this machine running normally again.

So if it was just a stuck relay, why wasn’t the heater circuit running? Why wouldn’t the machine start a cycle? Well, all these control boards run on algorithms. Don’t get scared by that word — it just means that the engineers have designed the board to make certain decisions if it receives certain inputs. If this, do this. That’s all it boils down to. In this particular case, we can pretty safely assume that the board was programmed to refuse to run when it sensed (through a sensing line) something strange like the motor running out of cycle. That’s the safest thing for it to do when it senses something is wrong.

Want to learn to read schematics and troubleshoot like a pro? Click below to check out our online Core Appliance Repair Training course right here at the Master Samurai Tech Academy.