As a reminder:

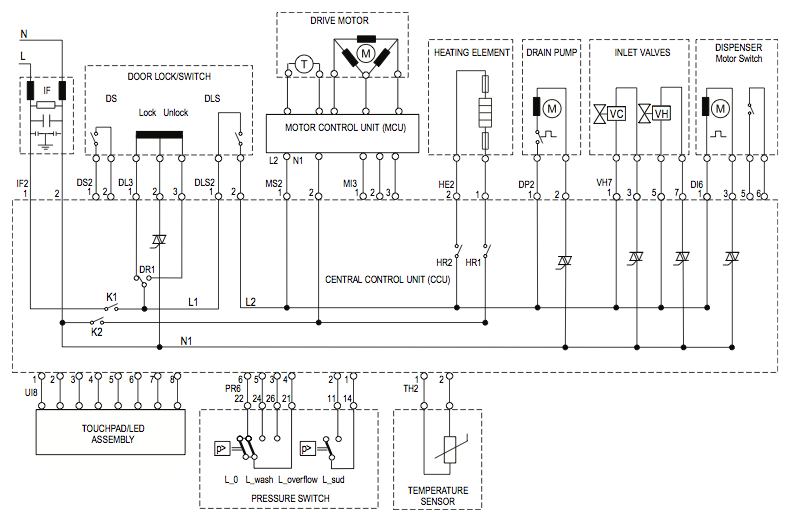

Q: In this washer, the drain pump is not running. You’ve already tested the drain pump motor winding and it is not open. Now you want to test the voltage supply from the CCU. From the options given below, which is the correct method of testing the drain pump voltage supply?

THE ANSWER: Disconnect DP2 and check voltage at the board using a loading meter with a low input impedance that draws current from the circuit.

“First off, do I need to know this?”

Yes, our students find being able to answer questions like these has made their job 1000x easier (we did the math), resulting in better job security and a higher salary. If you keep finding yourself stumped by unusual appliance issues, or keep having to return to homes because your repairs didn’t fix the problem, know that that doesn’t have to be the job. If you’re well-trained in electricity, schematic analysis, diagnostics, and more; the job can be pretty effortless and satisfying.

“Okay, I’ll bite, why is that the correct answer?”

Why? Well, first you must understand: 1) the importance of using loading meters for all AC measurements, and 2) how triacs work and why they can affect voltage measurements. If at any point you feel overwhelmed by the subject matter we discuss below, you would definitely benefit from our appliance repair training. With our training under your belt, the following information will make complete sense and become second-nature.

AC Testing

As a general rule, all AC voltage measurements should be made with the load connected. Why? AC circuits are subject to a type of failure called “failing under load.” A switch or load may test within specifications on an ohms or simple continuity test, but fail open when trying to carry operating current. Switches are especially likely to fail in this way. For this reason, professional technicians often prefer to work on live circuits when testing for voltage and current.

So then why did none of the answers state that DP2 was connected? To create a scenario where the choice of meter was critically important!

The Impact of Impedance

Every tech should have a “loading meter” in their tool bag. These meters actually place a load on the circuit being tested. Examples of loading meters are the LoZ setting on some digital multimeters (DMM), such as the Fluke 117, and the old-school solenoid voltage testers.

The VAC function on a typical DMM has an input impedance of about 50 mega ohms (that’s 50 million ohms). At these high input impedances, the current draw is minimal which means they do not place a load on the circuit being tested. It also means they can show a type of voltage called “Ghost Voltage” which has head-faked many appliance techs while troubleshooting a circuit.

Spooky Voltage?

Ghost voltage is a voltage that is capacitively coupled into an open-ended wire (think: open Neutral) by an adjacent live wire. A typical scenario is wires in a wire harness where the Neutral wire has an open but, since it is in physical proximity to the wire carrying Line voltage (the “Hot” wire), it will have some amount of voltage coupled into it. The result is that when you measure across the Line and Neutral wires in such a scenario, your DMM will report some amount of voltage, sometimes over 100 VAC. Yet the load doesn’t run (which is why you’re there troubleshooting). So, is this real voltage or just ghost voltage? How do you tell? Answer: use a loading meter.

The video below shows this in action:

Tricky Triacs

The other consideration in this particular case is the presence of a triac in the power supply for the drain pump.

Triacs are basically solid state relays. Like electromechanical relays, a small control voltage is used to control (or switch) a large working voltage. But there’s one little wrinkle with triacs versus electromechanical relays: triacs are *current controlled devices*. This means that there must be a minimum specified amount of current passing through the triac in order for the triac to fully “turn on” or close and thus complete the circuit. If the load is disconnected when you measure the power supply with a triac in it, you have removed the possibility for current to pass through the triac therefore the triac will not be closed. This results in ambiguous or meaningless measurements. For example, if the triac is in the Neutral, the Neutral will still be open and in an electrically “floating” condition, as we saw with the relay in the video.

For more information about triacs and how they work, read this article.

Bottom Line Best Practices

The bottom line with the foregoing discussion is this: even though it is best to test a power supply with the load connected, using a loading meter usually allows you get a reliable voltage measurement either way. Also, loading meters draw enough current to allow most triacs to fully turn on and close the circuit.

If you would like to learn more and become a better tech: